What is harmonic distortion?

Harmonics are currents or voltages with frequencies that are integer multiples of the fundamental power frequency being 50 or 60Hz (50Hz for European power and 60Hz for American power). For example, if the fundamental power frequency is 60 Hz, then the 2nd harmonic is 120 Hz; the 3rd is 180 Hz, etc. In modern test equipment today harmonics can be measured up to the 63rd harmonic. When harmonic frequencies are prevalent, electrical power panels and transformers become mechanically resonant to the magnetic fields generated by higher frequency harmonics. When this happens, the power panel or transformer vibrates and emits a buzzing sound for the different harmonic frequencies.

What causes harmonic distortion?

Harmonics are caused by and are the by-product of modern electronic equipment such as personal or notebook computers, laser printers, fax machines, telephone systems, stereos, radios, TVs, adjustable speed drives and variable frequency drives, battery chargers, UPS, and any other equipment powered by switched-mode power supply (SMPS) equipment. The above-mentioned electronic SMPS equipment is also referred to as non-linear loads. This type of non-linear loads or SMPS equipment generates the very harmonics they’re sensitive to and that originate right within your building or facility. SMPS equipment typically forms a large portion of the electrical non-linear load in most electrical distribution systems. There are basically two types of non-linear loads: single-phase and three-phase. Single-phase non-linear loads are prevalent in modern office buildings while three-phase non-linear loads are widespread in factories and industrial plants.

What does harmonic distortion do to the power at my facility?

In today’s environment, all computer systems use SMPS that convert utility AC voltage to regulated low voltage DC for internal electronics. These non-linear power supplies draw current in high amplitude short pulses. These current pulses create significant distortion in the electrical current and voltage wave shape. This is referred to as a harmonic distortion and is measured in Total Harmonic Distortion (THD). The distortion travels back into the power source and can affect other equipment connected to the same source.

Example: To give an understanding of this, consider a water piping system. Have you ever taken a shower when someone turns on the cold water at the sink? You experience the effect of a pressure drop to the cold water, reducing the flow of cold water. The end result is you get burned! Now imagine that someone at a sink alternately turns on and off the cold and hot water. You would effectively be hit with alternating cold and hot water! Therefore, the performance and function of the shower is reduced by other systems. This illustration is similar to an electrical distribution system with non-linear loads generating harmonics. Any SMPS equipment will create continuous distortion of the power source that stresses the facility’s electrical distribution system and power equipment.

What other effects besides distorting the shape of the voltage and current sinusoids, do harmonics cause?

Since non-linear loads produce harmonic currents with frequencies considerably higher than the power system fundamental frequency, these currents encounter much higher impedances as they propagate through the power system than does the fundamental frequency current. This is due to “Skin Effect” which is the tendency for higher frequency currents to flow near the surface of the conductor.

Since little of the high-frequency current penetrates far beneath the surface of the conductor, less cross-sectional area is used by the current. As the effective cross section of the conductor is reduced, the effective resistance of the conductor is increased. The higher resistance encountered by the harmonic currents will produce a significant heating of the conductor, since heat produced — or power lost — in a conductor is I2R, where “I” is the current flowing through the conductor. This increased heating effect is often noticed in two particular parts of the power system: neutral conductors and transformer windings.

Typical problems, together with before mentioned overheating in neutral conductors, transformers, or induction motors, include:

- Malfunctioning of microprocessor-based equipment.

- Deterioration or failure of power factor correction capacitors.

- Erratic operation of breakers and relays.

- Pronounced magnetic fields near transformers and switchgear.

- Large load currents in the neutral wires of a 3 phase system. Theoretically the neutral current can be up to the sum of all 3 phases therefore causing overheating of the neutral wires. Since only the phase wires are protected by circuit breakers of fuses, this can result in a potential fire hazard.

- Overheating of standard electrical supply transformers which shortens the life of a transformer and will eventually destroy it. When a transformer fails, the cost of lost productivity during the emergency repair far exceeds the replacement cost of the transformer itself.

- High voltage distortion exceeding IEEE Standard 1100-1992 “Recommended Practice for Powering and Grounding Sensitive Electronic Equipment” and manufacturer’s equipment specifications.

- High current distortion and excessive current draw on branch circuits exceeding IEEE Standard 1100-1992 “Recommended Practice for Powering and Grounding Sensitive Electronic Equipment” and manufacturer’s equipment specifications.

- High neutral-to-ground voltage often greater than 2 volts exceeding IEEE Standard 1100-1992 “Recommended Practice for Powering and Grounding Sensitive Electronic Equipment.”

- High voltage and current distortions exceeding IEEE Std. 519-1992 “Recommended Practices and Requirements for Harmonic Control in Electrical Power Systems.”

- Poor power factor conditions that result in monthly utility penalty fees for major users (factories, manufacturing, and industrial) with a power factor less than 0.9.

- Resonance that produces over-current surges. In comparison, this is equivalent to continuous audio feedback through a PA system. This results in destroyed capacitors and their fuses and damaged surge suppressors which will cause an electrical system shutdown.

- False tripping of branch circuit breakers.

Harmonic Distortion General Information

General Information – Harmonic Distortion

It is important to note that THD (Total Harmonic Distortion) levels above 5% can shorten the life of the electrical equipment and contribute to other issues with electronics such as unexplained glitches on computers and test & monitoring equipment and/or systems.

These issues can have harmful and/or costly effects on the overall health and functionality of your electrical distrbution system and it’s connected equipment.

To help understand the impact and significant role harmonic distortion can play, a bit of information concerning THD is warranted.

What is harmonic distortion?

Harmonics are currents or voltages with frequencies that are integer multiples of the fundamental power frequency being 50 or 60Hz (50Hz for European power and 60Hz for American power). For example, if the fundamental power frequency is 60 Hz, then the 2nd harmonic is 120 Hz; the 3rd is 180 Hz, etc. In modern test equipment today, harmonics can be measured up to the 63rd harmonic. When harmonic frequencies are prevalent, electrical power panels and transformers become mechanically resonant to the magnetic fields generated by higher frequency harmonics. When this happens, the power panel or transformer vibrates and emits a buzzing sound for the different harmonic frequencies.

What causes harmonic distortion?

Harmonics are caused by and are the by-product of modern electronic equipment such as personal or notebook computers, laser printers, fax machines, telephone systems, stereos, radios, TVs, adjustable speed drives and variable frequency drives, battery chargers, Uninterruptable Power Supplies, and any other equipment powered by switched-mode power supply (SMPS) equipment. The above-mentioned electronic SMPS equipment is also referred to as non-linear loads. These types of non-linear loads or SMPS equipment generate the very harmonics they are sensitive to and that originate right within your building or facility. SMPS equipment typically forms a large portion of the electrical non-linear load in most electrical distribution systems. There are two basic types of non-linear loads: single-phase and three-phase. Single-phase non-linear loads are prevalent in modern office buildings while three-phase non-linear loads are widespread in factories and industrial plants.

What does harmonic distortion do to the power at my facility?

In today’s environment, all computer systems use SMPS that convert utility AC voltage to regulated low voltage DC for internal electronics. These non-linear power supplies draw current in high amplitude short pulses. These current pulses create significant distortion in the electrical current and voltage wave shape. This is referred to as a harmonic distortion and is measured in Total Harmonic Distortion (THD). The distortion travels back into the power source and can affect other equipment connected to the same source.

Example: To give an understanding of this, consider a water piping system. Have you ever taken a shower when someone turns on the cold water at the sink? You experience the effect of a pressure drop to the cold water, reducing the flow of cold water. The end result is you get burned! Now imagine that someone at a sink alternately turns on and off the cold and hot water. You would effectively be hit with alternating cold and hot water! Therefore, the performance and function of the shower is reduced by other systems. This illustration is similar to an electrical distribution system with non-linear loads generating harmonics. Any SMPS equipment will create continuous distortion of the power source that stresses the facility’s electrical distribution system and power equipment.

What other effects besides distorting the shape of the voltage and current sinusoids, do harmonics cause?

Since non-linear loads produce harmonic currents with frequencies considerably higher than the power system fundamental frequency, these currents encounter much higher impedances as they propagate through the power system than does the fundamental frequency current. This is due to “Skin Effect” which is the tendency for higher frequency currents to flow near the surface of the conductor.

Since little of the high-frequency current penetrates far beneath the surface of the conductor, less cross-sectional area is used by the fundamental current. As the effective cross section of the conductor is reduced, the effective resistance of the conductor is increased. The higher resistance encountered by the harmonic currents will produce a significant heating of the conductor, since heat produced — or power lost — in a conductor is I2R, where “I” is the current flowing through the conductor. This increased heating effect is often noticed in two particular parts of the power system: neutral conductors and transformer windings.

Typical problems, together with before mentioned overheating in neutral conductors, transformers, or induction motors, include:

- Malfunctioning of microprocessor-based equipment.

- Deterioration or failure of power factor correction capacitors.

- Erratic operation of breakers and relays.

- Pronounced magnetic fields near transformers and switchgear.

- Large load currents in the neutral wires of a 3 phase system. Theoretically the neutral current can be up to the sum of all 3 phases therefore causing overheating of the neutral wires. Since only the phase wires are protected by circuit breakers of fuses, this can result in a potential fire hazard.

- Overheating of standard electrical supply transformers which shortens the life of a transformer and will eventually destroy it. When a transformer fails, the cost of lost productivity during the emergency repair far exceeds the replacement cost of the transformer itself.

- High voltage distortion exceeding IEEE Standard 1100-1992 “Recommended Practice for Powering and Grounding Sensitive Electronic Equipment” and manufacturer’s equipment specifications.

- High current distortion and excessive current draw on branch circuits exceeding IEEE Standard 1100-1992 “Recommended Practice for Powering and Grounding Sensitive Electronic Equipment” and manufacturer’s equipment specifications.

- High neutral-to-ground voltage often greater than 2 volts exceeding IEEE Standard 1100-1992 “Recommended Practice for Powering and Grounding Sensitive Electronic Equipment.”

- High voltage and current distortions exceeding IEEE Std. 519-1992 “Recommended Practices and Requirements for Harmonic Control in Electrical Power Systems.”

- Poor power factor conditions that result in monthly utility penalty fees for major users (factories, manufacturing, and industrial) with a power factor less than 0.9.

- Resonance that produces over-current surges. In comparison, this is equivalent to continuous audio feedback through a PA system. This results in destroyed capacitors and their fuses and damaged surge suppressors which will cause an electrical system shutdown.

- False tripping of branch circuit breakers.

Again as you can see harmonic distortion can be destructive and costly to your electrical system, equipment and devices as well as your businesses bottom line.

Read MoreLeading & Lagging Power Factor Differences

What is the difference between lagging power factor and leading power factor?

Power factor is the ratio of watts (true power) to VA (volt-amperes, also called apparent power). Where the load is resistive only, the power factor is one, or unity, because the voltage waveform and the current waveform are in phase. Thus, for resistive loads only, true power and VA are the same. Where the load is reactive, the load stores energy, releasing it during a different part of the cycle. This shifts the current waveform so that it is offset, or out of phase with the voltage waveform.

Reactive loads can be inductive (electric motors), capacitive, or non-linear (rectifier power supplies). When the load is inductive, the inductance tends to oppose the flow of current, storing energy then releasing it later in the cycle. The current waveform lags behind the voltage waveform. When the load is capacitive, the opposite occurs, and the current waveform leads the voltage waveform.

Therefore, lagging vs. leading is another way of saying the net reactance is either inductive or capacitive. This is slightly simplistic, and what we are talking about above is really DPF, or Displacement Power Factor. Non-linear loads do not really shift the current waveform, they distort it. The current waveform starts to look like a square wave, and square waves contain harmonics. So non-linear loads add harmonic distortion, and this tends to mimic a capacitively reactive load, adding some leading power factor.

Therefore, when we say power factor, we really must include DPF plus harmonic distortion in total. One memory aid that may help to remember all this is: ELI the ICE man The L in ELI means inductance. The E (voltage) comes first, then the I (current) lags behind. Inductive reactance produces a lagging power factor. The C in ICE means capacitance. The I (current) comes first (leads) then the E (voltage) comes later. Capacitive reactance produces a leading power factor.

Remember, it’s always the current waveform that is affected by the reactive load, so you have to think about whether the current is leading or lagging. Most reactive loads are inductive, so at most sites the PF is lagging. One cool tidbit is that capacitive reactance cancels out inductive reactance. So if we have a building full of motors, we can add a bunch of capacitors to improve our power factor, meaning we get as close to unity as we can. Thus, power factor correction capacitors are made just for this purpose.

Read MoreWhat is reactive power?

This document covers; The Concepts of Reactive Power, Low Power Factor and Methods of Power Factor Improvement.

Power factor is defined as the ratio of real power to apparent power. This definition is often mathematically represented as kW/kVA, where the numerator is the active (real) power and the denominator is the (active+ reactive) or apparent power. Though the definition is very simple, the concept of reactive power is vague or confusing even to many of those who are technically knowledgeable.

Explanation for reactive power says that in an alternating current system, when the voltage and current go up and down at the same time, only real power is transmitted and when there is a time shift between voltage and current both active and reactive power are transmitted. But, when the average in time is calculated, the average active power exists causing a net flow of energy from one point to another, whereas average reactive power is zero, irrespective of the network or state of the system. In the case of reactive power, the amount of energy flowing in one direction is equal to the amount of energy flowing in the opposite direction (or different parts -capacitors, inductors, etc- of a network, exchange the reactive power). That means reactive power is neither produced nor consumed.

But, in reality we can measure reactive power losses, many different types of devices, equipment and systems can be introduced to manage or mitigate reactive power. These types of compensation are to reduce electricity consumption and cost.

Confusions

The indisputable law of conservation of energy states, “energy can neither be created nor be destroyed”; yet we talk about Conservation of Energy!! The confusions erupt when we yell out the theory of conservation ignoring other theories of thermodynamics – like one, which states that entropy (low quality energy) is ever increasing. Mathematical sum of total energy has no meaning to an energy user, and hence he must be concerned about the efficiency of conversion and conservation of energy. Similarly, though we can mathematically prove that loss in reactive power is no real loss and no reactive energy is lost, we have several other reasons to be concerned about reactive power improvement. This can be better explained by physical analogies.

Physical Analogies

Suppose I want to fill a water tank with water, one bucket at a time. Only way is to climb a ladder, carrying a bucket of water and pouring the water into the tank. Once I fill up the tank, then I have to go down the ladder to get more water. In this one cycle of going up the ladder and coming down I have done some “work” or “the energy required to go up is more than the energy required for coming down.”

If I had climbed the ladder with an empty bucket, and I had come down with the same bucket I am not doing any work. The energy for upward and downward motion is the same. Though I have not done any work – worth paying for- I require some energy.

That is, the energy that it takes to go up and down a ladder carrying nothing either way requires reactive power, but no real power. The energy that it takes to go up a ladder carrying something and come down without carrying anything requires both real power and reactive power.

The analogy can be extended for explaining 3 phase system; it is like putting 3 ladders going up to the tank and having 3 people climb up in sequence and pouring their water into the tank such that there is always a steady flow.

Here is a simplistic analogy called, the “Beer Mug analogy”

Power Factor = Active power/Apparent power = kW/kVA

= Active power/ (Active Power+Reactive Power)

= kW/(kW+kVAr)

= Beer/(Beer+Foam)

The more foam (higher kVAr) indicates low power factor and vice versa.

(In Electrical terms kW, kVA, and kVAr are vectors and we have to take the vector sum).

What causes low power factor in Electrical System

Various causes, which can be attributed for low PF, may be listed as follows.

- Inductive loads. Especially lightly loaded induction motors, and transformers.

- Induction Furnaces

- Arc Lamps and arc furnaces with reactors.

- Fault limiting reactors

- High Voltage.

- Harmonic distortion up to 63rd harmonic

The reactive power required by these loads increases the amount of apparent power in the distribution system and this increase in reactive power and apparent power results in a lower power factor.

How to improve Power Factor

Power factor can be improved by adding consumers of reactive power in the system like Capacitors or Synchronous Motors. It can also be improved by fully loading induction motors and transformers and also by using higher rpm machines. Removing or reducing the harmonic distortion. Improving and regulating of the voltage sine wave. Usage of automatic tap changing system in transformers can also help to maintain better power factor.

Question: Under which circumstances may power factor corrections..

A) reduce electricity consumption in a plant

Answer: Power factor improvement in plant, by adopting any one of the aforementioned options, will generally compensate for the losses and reduce current loadings on supply equipment, i.e.; cables, switchgear, transformers, generating plant, etc. That means power factor corrections – whenever there is scope for correction- will reduce electricity consumption in the plant and in turn the electricity cost. Many of these losses are not properly monitored in many industries and hence the savings are not quantified. This may be one of the reasons for the argument that PF improvement reduces only electricity costs; in case the power utility is offering a tariff where a reactive power demand charge are part of the monthly electricity bill.

Power factor improvement will lead to reduction in electricity consumption, when it is done at the equipment level or at the Control Center level (case studies have shown the savings in both these instances)

B) reduce electricity costs only

Answer: Power factor correction will reduce electricity cost only, when the plant receiving power from a common grid carries out the correction at the supply voltage/incoming voltage level, just to compensate for the reactive power drawn from the grid. But, even this improvement in PF may not always reduce the electricity cost as the contract demand in a plant is very often fixed on a fictitious consumption in the plant. On many occasions contract demand is fixed based on the future expansion plans, and based on the high diversity factor taken during design stages. In most of the cases the Utilities charge for a minimum contract demand irrespective of the consumption and a reduction in kVA may not produce any benefit as long as the contract demand is re-fixed to actual value.

Generally PF is improved to 0.95-0.98, as improving PF further to unity (1.0) may lead to higher payback periods.

C) reduce both electricity costs and electricity consumption

Answer: In all other cases, other than the above mentioned exception, whenever improvement of power factor is carried out, it will eventually lead to reduction in electricity consumption and hence electricity cost.

However, payback on investment due to power factor correction depends on the type of installation and various other factors like power tariff, loading pattern of equipment, method of power generation/utilization, operating philosophy of the plant etc.

Read MoreCauses and Effects of Transient Voltages

What are transient voltages?

“Transients”, a term we will use for simplicity here, are actually “Transient Voltages”. In terms that are more familiar… “surges” or “spikes”. Basically, transients are momentary changes in voltage or current that occur over a short period of time.

This interval is usually described as approximately 1/16 (one sixteenth) of a voltage cycle (in the US, about 1/60th of a second) or about 1 milliseconds (milli = .0 0 1–one thousandths…In laymen’s terms, .0166 seconds……or really darned quick.).

Voltage transients normally last only about 50 microseconds (micro = .0 0 0 0 0 1–one millionth) and current transients last typically 20 microseconds according to the ANSI C62.41-1991 which is the standard for transients in facilities operating under 600 Volts.

Key Points

- Transient activity is believed to account for 80% of all electrically-related downtime.

- Lightning accounts at least 5% of Insurance claims and costs an average of $13,000 per occurrence.

- Effective transient voltage suppression equipment can double or triple the life of electrical and electronic equipment.

- A systems approach to transient voltage surge suppression can result in dramatic performance in terms of return-on investment.

- Transient Voltage Surge Suppression is the most immediately apparent, and the most cost-effective means of improving your power quality.

Here’s the technical definition:

(ANSI std. 1100-1992) A sub cycle disturbance in the AC waveform that is evidenced by a sharp brief discontinuity of the waveform. Transients may be of either polarity and may be of additive or subtractive energy to the nominal waveform.

Transients are divided into two categories which are easy to identify: impulsive and oscillatory. If the mains signal is removed, the remaining waveform is the pure component of the transient. The transient is classified in the impulsive category when 77% of the peak-to-peak voltage of the pure component is of one polarity. Each category of transient is subdivided into three types related to the frequencies contained. Each type of transient can be associated with a group of phenomena occurring on the power system.

The impulsive low-frequency transient rises in 0.1 ms and lasts more than 1 ms. Its companion, the oscillatory low-frequency transient, contains frequency components up to 5 kHz. These types are the most common transients recorded on a power system. They are not only easily propagated but they can also be amplified by a power-system resonance phenomenon. Measurement of these types of transients should be useful for all classes of application (benchmarking, legal, trouble shooting and laboratory)

The medium-frequency impulsive transient lasting between 50 ns to 1 ms and oscillatory transients between 5 and 500 kHz are less frequent than the low-frequency types but have much higher amplitude. These transients may not propagate as easily as the low-frequency types but may cause arcing faults on the power distribution system which result in voltage sag on many user power systems. It is most appropriate to measure these types of transients for trouble shooting and laboratory classes.

High-frequency types with high amplitude can be observed only near where the phenomenon occurs. The high-frequency impulsive transient has duration below 50 ns and the frequency of the high frequency oscillatory t ype ranges between 0.5 and 5 MHz. These measurements are useful for laboratory and troubleshooting classes of application.

Characteristics of the Transient Voltage Waveform

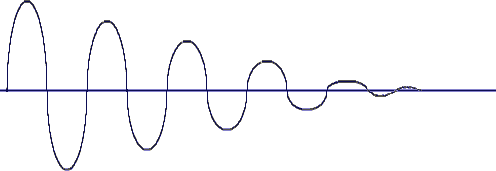

The most common transient is the “oscillatory transient”. It is sometimes described as a “ringing transient”. This type of transients is characterized by swings above and below the normal line voltage.

The most common transient is the “oscillatory transient”. It is sometimes described as a “ringing transient”. This type of transients is characterized by swings above and below the normal line voltage.

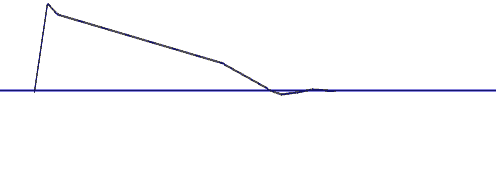

The other type (impulse) transient, is more easily explained as a “one-shot” type of event, and it is characterized by having more than 77% of it being one pulse above the line voltage. A lightning strike can be composed of multiple transients of this type.

Even these transients can be broken up into other categories identified by their frequency.

1. Mid-to-Low Frequency Transients, like lightning and utility capacitor switching propagate (travel) very well on electrical systems. Higher amplitudes tend to be damped by the building’s distribution system at voltages above 16,000 volts. There is almost no damping below 10,000 volts.

2. High Frequency transients, however, are usually only seen near the source. This means that surge suppression equipment installed a distance away will never see the effect. It is for this reason that multiple suppressors are recommended within the facility.

Where do Transient voltages come from?

Transients can be generated internally, or they can come into a facility from external sources. The least common of the two are externally generated transients. They have been described as “electronic rust”.

External sources:

Lightning is the most well known of the externally generated transients. Most lightning transients are not actually the result of direct lightning strikes….they are most often “induced” onto conductors as lightning strikes near the power line. The large electric fields generated during a discharge can couple into the power system, creating induced transients. A cloud-to-cloud discharge can generate a 70 Volts per meter electric field. On a 1/2-mile length of transmission line this is equal to a 56,000-volt transient–and it didn’t even touch the line!

Other externally generated transients may also be imposed on power lines through normal utility operations. Switching of facility loads, opening and closing of disconnects on energized lines, switching of capacitor banks, re-closure operations and tap changing on transformers can all cause transients.

Poor or loose connections in the distribution system can also generate transients. They may be caused by high winds, which can blow one power line into another or blow tree limbs into the lines causing arcing. You will probably be able to hear a buzzing sound and see sparks when the arc occurs, or you may even be able to smell the burnt insulation around the arc.

Accidents and human error account for some externally generated transients since most power lines are run above-ground. Animals and weather can also produce conditions, which generate transients.

Another common source, not commonly known, is neighboring businesses. If you share a transformer with other users, any transient activity generated on his premises will be seen at your electrical main. Remember, you are both physically connected at the secondary side (some people call it the “south side”) of the transformer.

Internal Sources:

The vast majority of transients are produced within your own facility. The main culprits are device switching, static discharge, and arcing.

Each time you turn on, turn off, load, or unload an inductive device, you produce a transient. Inductive devices are those devices that use “magnetic mass” to function. Examples of inductive loads are motors and transformers. The inductive “kick” from a 5-horsepower motor turning on can produce a transient in excess of 1,000 volts. A motor with a faulty winding, commutator, or other insulation faults can produce a continuous stream of transients exceeding 600 volts! Even transformers can produce a large transient, particularly when energizing. Interestingly enough, this isn’t produced the way many people think (from the sudden load on the system), but is a result of the collapse of the magnetic field upon energizing the transformer.

Static electricity (also called “electrostatic discharge”) can generate up to 40,000 volts. This type of hazard is very dependent upon environmental conditions and areas with lower humidity have the worst problems.

Arcing can generate transients from a number of sources. Faulty contacts in breakers, switches, and contactors can produce an arc when voltage jumps the gap. When this gap is “jumped” the voltage rises suddenly and the most common effect is an oscillatory-ring-type transient. Faulty connections and grounds can produce arcing.

Common Internal Sources of Transient Activity

| Photocopiers | PC Power Supplies | Laser Printers | Electronic Ballasts |

| Welders | Power Factor Correction Equipment | Power Supplies | Temperature Controllers |

| Motor Controllers | Pumps | Inverters | Compressors |

| Generators | Variable Speed Motors | Standard Electric Motors | High-Frequency Lighting Power Supplies |

How Do Transients “Travel”?

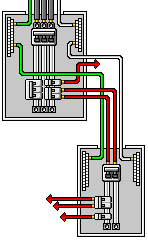

The common aspect of all these internally generated voltages is your electrical distribution system. Your facility wiring is designed to transmit electricity with the least impedance possible so that maximum efficiency is maintained. This same efficiency works to transfer the transients produced throughout your facility with minimal obstruction.

All of your panels are physically bonded together by multiple means. Transient activity “seen” at one panel is easily transmitted to all other panels within your system, dependent upon transient frequency and magnitude.

You may even have transient activity you are unaware of even after you have “measured” your power quality. This is because high-frequency transient activity must be measured near its source. Many facility managers check power quality at the service entrance panel (because this is where the utility companies tend to do it).

What are the effects of transient activity?

Electronic Equipment:

Electronic devices may operate erratically. Equipment could lock up or produced garbled results. These types of disruptions may be difficult to diagnose because improper specification and installation of transient voltage surge suppression equipment can actually INCREASE the incidents of failure as described above.

Electronic devices may operate at decreased efficiencies. Damage is not readily seen and can result in early failure of affected devices. Unusually high frequency of failures in electronic power supplies are the most common symptom.

Integrated circuits (sometimes called “electronic chips”) may fail immediately or fail prematurely. Most of the time, the failure is attributed to “age of the equipment”. Modern electronic devices provided clean, filtered power should outlast the mechanical devices they control.

Motors:

Motors will run at higher temperatures when transient voltages are present. Transients can interrupt the normal timing of the motor and result in “micro-jogging”. This type of disruption produces motor vibration, noise, and excessive heat. Motor winding insulation is degraded and eventually fails. Motors can become degraded by transient activity to the point that they produce transients continually which accelerates the failure of other equipment that is commonly connected in the facility’s electrical distribution system. Transients produce hysteresis losses in motors that increase the amount of current necessary to operate the motor. Transients can cause early failures of electronic motor drives and controls.

Lighting:

Transient activity causes early failure of all types of lights. Fluorescent systems suffer early failure of ballasts, reduced operating efficiencies, and early bulb failures. One of the most common indicators of transient activity is the premature appearance of black “rings” at the ends of the tubes. Transients that are of sufficient magnitude will cause a sputtering of the anodes–when these sputters deposit on the insides of the tube, the result is the black “ends” commonly seen. Incandescent lights fail because of premature filament failures. The same hysteresis losses produced in motors are reproduced in transformers. The results of these losses include hotter operating temperatures, and increased current draws. Do you want to see a graphic illustration of the results of transient activity on fluorescent tubes? Look at the ends of your tubes…..see those dark rings? Effective transient suppression will eliminate those rings and make your bulbs last 4 to 6 times longer.

Electrical Distribution Equipment:

The facility’s electrical distribution system is also affected by transient activity. Transient degrade the contacting surfaces of switches, disconnects, and circuit breakers. Intense transient activity can produce “nuisance tripping” of breakers by heating the breaker and “fooling” it into reacting to a non-existent current demand. Electrical transformers are forced to operate inefficiently because of the hysteresis losses produced by transients and can run hotter than normal.

Read More